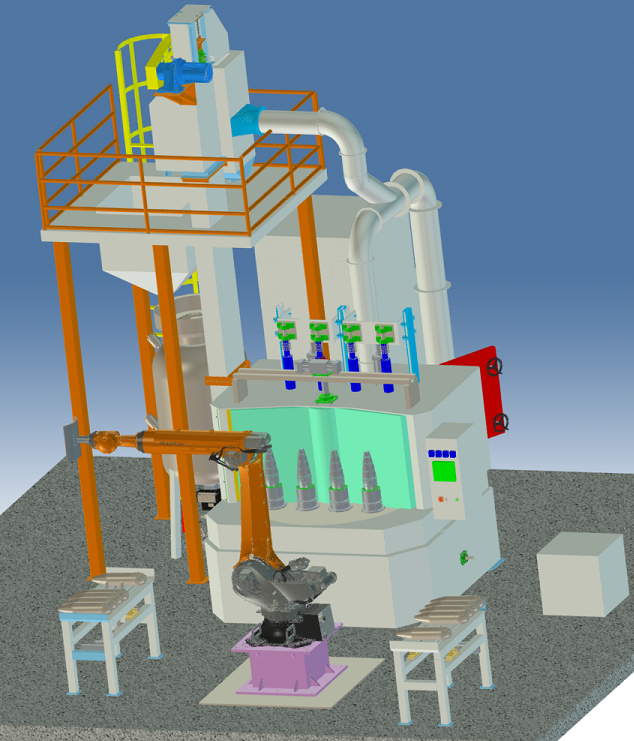

Mochini oa ho hloekisa lebota ka hare ho khetla

Mochini o thunyang leboteng le ka hare la likhetla ke sesebelisoa se itirisang ka ho khetheha se etselitsoeng ho tlosa masala, likarolo tsa oxide le mafome ka har'a bokahare ba mekotla e joalo. Mosebetsi oa mantlha o kenyelletsa ho hloekisoa le ho matlafatsa holim'a metsi ka-ka lebelo le phahameng la mecha ea litaba, joalo ka steel shot kapa ceramic shot.

Tlhaloso e Felletseng ea Likarolo Tsa Sehlooho le Mesebetsi ea Mochini oa ho Hloekisa Lebota la Shell ka hare le ka ntle.

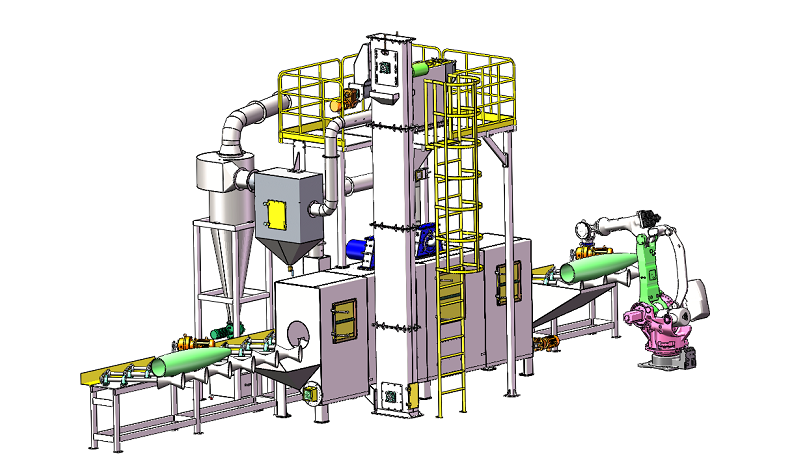

1. Projectile Circulation System

Shot Storage le Supply Device

Mosebetsi: E boloka mecha ea phatlalatso ea abrasive (mohlala, stainless steel shot, cast steel shot) le ho fana ka eona ka bongata sebakeng se thunyang ka valve e laoloang kapa tsamaiso e tsamaisang, ho netefatsa khatello e tsitsitseng ea ente.

Shot Recovery Device

Mosebetsi: E bokella mecha ea phatlalatso ea abrasive ka li-screw conveyors, li-backet lifts, kapa lisebelisoa tsa pneumatic recovery ebe e li khutlisetsa sebakeng sa polokelo, e etsa mokhoa o koalehileng{0}} oa loop circulation system ho fokotsa tahlehelo ea thepa.

Sesebelisoa sa ho Hlopha le ho Hloekisa Shot

Mosebetsi: E sebelisa li-skrini tse thothomelang le lihlopha tsa moea ho arola li-pellets tse robehileng, lerōle le litšila, ho netefatsa botšepehi ba mecha ea litaba e senyang le ho boloka bohloeki bo sebetsang hantle.

2. Thunya Blasting System

Inner Wall Shot Blasting Device

Sesebelisoa sa Kantle sa Wall Shot Blasting

Mosebetsi: E potlakisa mecha ea phatlalatso ea abrasive ho lebelo le phahameng (60-100 m / s) ho sebelisa mabili a centrifugal kapa li-nozzles tsa moea tse hatelitsoeng le ho li lebisa likarolong tse ka hare le tse ka ntle tsa khetla, ho netefatsa hore li koahetsoe ka botlalo.

Multi-Angle Nozzle Adjustment Mechanism

Mosebetsi: E lokisa angle ea ho fafatsa ka matsoho a mochini kapa li-nozzles tse bilikang ho netefatsa ho hloekisoa ka botlalo ha meaho e rarahaneng ea mabota, joalo ka likhoele le li-grooves, e tlosa matheba a foufetseng.

3. Shell Positioning le Conveying System

Automatic Clamping le Rotation Mechanism

Mosebetsi: E sireletsa khetla ka ho sebelisa li-hydraulic kapa pneumatic fixtures le ho e potoloha ho potoloha axis ea eona ka enjene, ho netefatsa hore lebota le ka hare le pepeseha ka mokhoa o ts'oanang ha ho qhomisoa.

Conveyor Line (Mofuta oa Chain/Roller Conveyor)

Mosebetsi: Ka tsela e iketsang e tsamaisa likhetla tsa likhetla ho kena le ho tsoa ka har'a seteishene sa ts'ebetso, li hokahanya lits'ebetso tsa ho laolla le ho laolla le ho nolofalletsa ho kopanngoa mehala ea tlhahiso e ikemetseng.

4. Ho Tlosa Lerōle le Tsamaiso ea Tšireletso ea Tikoloho

-Sek'habolli sa Lerōle se Sebetsang (Mokotla/Mofuta oa Cartridge)

Mosebetsi: E tšoara lerōle la tšepe le lithōle tse hlahisoang nakong ea ho qhomisoa, ho etsa bonnete ba hore mesi e finyella litekanyetso tsa tšireletso ea tikoloho (mohlala, PM10 Ka tlase kapa ho lekana le 20 mg/m³).

Sekoaelo sa ho Ikhetholla lerata

Mosebetsi: E fokotsa maemo a lerata a ts'ebetso (hangata a ka tlase ho 85 dB), kahoo e ntlafatsa tikoloho ea ts'ebetso ka kakaretso.

5. Tsamaiso ea ho laola

PLC/HMI Control Center

Mosebetsi: E lumella basebelisi ho seta liparamente joalo ka nako ea ho thunya, khatello le sekhahla sa phallo ea abrasive. E boetse e beha leihlo boemo ba lisebelisoa (mohlala, boemo ba sethunya, mocheso oa koloi) hape e ts'ehetsa tlhahlobo ea liphoso le lialamo.

Sistimi e Ikemetseng ea Kutlo

Mosebetsi: E lemoha boemo le boemo ba ho hloekisa khetla ea khetla e sebelisa li-photoelectric kapa li-sensor tsa khatello, e nolofalletsang liphetoho tse feto-fetohang nakong ea ts'ebetso.

6. Lisebelisoa tse Thusang

Sesebelisoa sa Lubrication le Cooling

Mosebetsi: E fana ka lubrication le ho pholisa bakeng sa likarolo tsa bohlokoa joalo ka li-bearings tse ka har'a yuniti e thunyang, ka ho etsa joalo e lelefatsa bophelo ba ts'ebeletso ea lisebelisoa.

Sesebelisoa sa Tšireletseho sa Interlock

Mosebetsi: E kenyelletsa li-switches tsa taolo ea phihlello le li-buttons tsa ho emisa ts'ohanyetso ho netefatsa hore lisebelisoa li koalehile nakong ea tlhokomelo le ho thibela ts'ebetso ea kotsi.

Mokhoa o Tloaelehileng oa Ts'ebetso

Khaketla ea khetla e feptjoa ka bo eona ka har'a sistimi → e behiloe 'me e tlanngoe → e fetoleloa ka phaposing e thunyang.

{{0}mecha ea litaba e senyang khatello e phahameng e fafatsoa leboteng le ka hare ha sistimi e ntse e hlaphoheloa, e hlophisa, le ho tlatsa mecha ea litaba ka nako e le 'ngoe.

Ha ho phetheloa ts'ebetso ea ho hloekisa, mecha ea litaba e senyang e khaotsa ho ntšoa, casing e khutlisetsoa morao, 'me khetla e hloekisitsoeng e lokolloa ka bo eona.

Nakong eohle ea ts'ebetso, mokhoa oa ho tlosa lerōle o ntse o sebetsa ho boloka tikoloho e hloekileng ea ho sebetsa.

Lintlha tsa Tekniki tsa Mochini oa ho Hloekisa oa Shot Blasting bakeng sa Shell Inner Walls

Sesole-Ho Nepa ha Kereiti: E khona ho hloekisa mabota a tebileng a ka hare ka botebo-ho{2}}karolelano ea bophara bo fetang 10, ho finyella ho khoasolla ha Ra Less ho feta kapa ho lekana le 1.6 μm.

Ho ikamahanya le maemo: E lumellana le lisebelisoa tse fapaneng, ho kenyeletsoa likhase tsa tšepe le aluminium alloy.

Phello e Matlafatsang: Ts'ebetso ea ho phunya e eketsa matla a mokhathala a lebota le ka hare ka ho baka khatello ea maikutlo e fetang -200 MPa.

Lisebelisoa tse joalo li sebelisoa haholo lits'ebetsong tsa sesole le tsa sefofane 'me li tlameha ho lumellana le litekanyetso tse amehang tsa sesole, tse kang GJB 150A-2009.